研究

研究

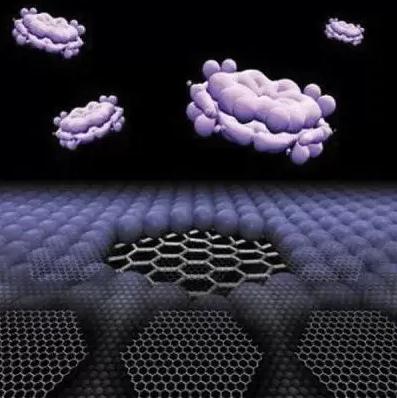

钠金属负极由于其高的比容量、低的氧化还原电位以及资源优势被认为是钠电池极佳的负极材料。然而,不稳定的固体电解质界面(SEI)以及钠枝晶生长问题严重阻碍了其实际应用。因此,采用适当的保护策略实现钠金属负极稳定及高效循环是非常必要的。通常在钠金属负极表面构建人工界面层不仅可以有效实现钠均匀沉积/剥离,而且可有效缓解钠金属负极在电化学过程中的体积变化以及抑制钠枝晶生长。为此,该综述归纳总结了人工界面层策略改善钠金属负极的研究进展。首先讨论了自发形成的SEI膜的基本性质,其存在稳定性差、韧性差、机械强度低等问题。针对此,提出构建无机、有机和无机-有机复合人工界面层保护钠金属负极,实现无枝晶钠沉积/剥离。含钠无机材料通常具有高剪切模量、耐腐蚀、结构稳定、高离子电导率等优点,但脆性大;有机材料通常具有结构可设计性、官能团多样性以及高机械韧性特点,但稳定性较弱;无机-有机复合保护膜结合了上述两者的优势,可构建综合性能优异的人工界面层。文中详细阐述了这三种人工界面膜的实施方法与改性效果。最后,建议对人工界面膜持续优化以及采用先进表征技术、理论计算和模拟等深入研究界面稳定性机理。...

研究

The rich-nickel LiNi1-x-yCo_xMn_yO2(NCM)/LiNi1-x-yCo_xAl_yO2(NCA) ternary layered cathode materials are considered as one of the most promising lithium battery cathode materials due to its high specific capacity and low cost.However,the nickel-rich NCM/NCA ternary layered cathode materials are sensitive to H2O and CO2 in the air,and is easy to generate residual alkali compound LiOH/Li2CO3(RLCs) on the surface.The existence of RLCs will dramatically deteriorate the thermal stability and electrochemical performance of nickel-rich ternary layered cathode materials,resulting in its large-scale commercial application faced severe challenges.This paper firstly reviewed the composition and formation mechanism of RLCs,and systematically summarized the failure mechanisms of materials caused by RLCs,such as microcrack propagation,Li~+/Ni~(2+) mixing,interfacial side reactions and lattice phase transformation.Meanwhile,the common RLCs removal strategies were also introduced.The research progress of deionized water washing,anhydrous ethanol washing,solution washing and subsequent integrated treatment in removing RLCs were deeply reviewed.In addition,the influencing mechanisms of washing process for the structure,morphology and electrochemical performance of high nickel ternary cathode materials were also highlighted.Finally,the characteristics of the solution washing strategy were summarized,and the future research and development of removal process for residual alkali compounds on the surface of rich-nickel NCM/NCA ternary layered cathode material were also prospected....

Copyright©2002-2025 Cnpowder.com.cn Corporation,All Rights Reserved